The landscape of wholesale frozen vegetables has transformed dramatically in recent years, with frozen fries, broccoli, and garlic emerging as frontrunners in the global food supply chain. These versatile ingredients have become essential components for food service businesses, retailers, and institutional buyers worldwide. The current market presents an exceptional opportunity with abundant supply and competitive pricing, making it an ideal time for bulk purchases and strategic inventory management.

Market analysts have observed a significant uptick in frozen vegetables wholesale transactions, particularly for these three products. The combination of extended shelf life, consistent quality, and year-round availability has positioned these items as smart choices for businesses looking to optimize their food cost management while maintaining high-quality standards.

Current production facilities are operating at peak efficiency, utilizing advanced flash-freezing technologies that preserve both nutritional value and texture. The robust storage infrastructure ensures consistent temperature control throughout the supply chain, maintaining product quality from processing centers to final delivery. This sophisticated system enables suppliers to maintain large inventories while guaranteeing product freshness.

State-of-the-art warehouse facilities equipped with modern cold storage systems have significantly increased the available stock of frozen vegetables wholesale. This expanded capacity has created favorable market conditions, resulting in competitive pricing structures that benefit bulk buyers and distributors.

The streamlined logistics network supporting frozen vegetables wholesale distribution has been optimized for efficiency and reliability. Advanced tracking systems and temperature-monitored transportation ensure product integrity throughout the delivery process. This enhanced supply chain management has reduced overhead costs, allowing suppliers to offer more attractive pricing to their customers.

Strategic positioning of distribution centers has minimized delivery times and improved product accessibility across different regions. This efficient network enables quick response to market demands and ensures consistent supply throughout the year.

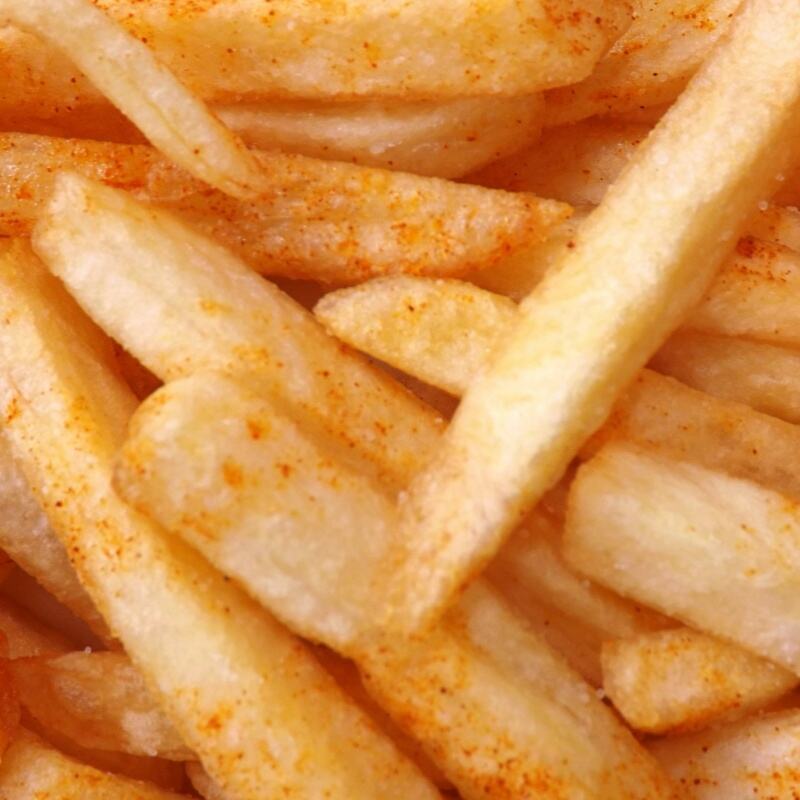

The frozen fries segment has experienced remarkable growth, driven by increasing demand from quick-service restaurants and institutional food services. These premium products are processed using advanced cutting and freezing techniques that ensure consistent shape, size, and golden-brown cooking results. The current market offers various cuts and specifications to meet diverse customer requirements.

Bulk buyers can now access high-quality frozen fries at exceptional prices, thanks to increased production capacity and optimized processing methods. The product's versatility and consistent cooking performance make it a reliable choice for food service operations of all sizes.

Fresh-frozen broccoli has gained significant traction in the frozen vegetables wholesale market, particularly among health-conscious food service providers and institutional kitchens. The quick-freezing process locks in essential nutrients and maintains the vegetable's natural color and texture, making it an excellent choice for various culinary applications.

Current market conditions offer attractive pricing for bulk purchases of frozen broccoli, supported by abundant harvests and efficient processing operations. The product's versatility in both hot and cold preparations has increased its appeal among professional kitchens and food manufacturers.

The frozen garlic segment has evolved to meet the growing demand for convenient, ready-to-use ingredients in commercial kitchens. Available in various forms – from whole cloves to minced preparations – frozen garlic products offer consistency in flavor and significant time savings in food preparation.

Current market supplies allow for competitive pricing on bulk orders, making it an opportune time for businesses to stock up on this essential ingredient. The preserved fresh flavor and extended shelf life make frozen garlic an economical choice for large-scale food operations.

The current market conditions in frozen vegetables wholesale present unique opportunities for effective cost management. Bulk purchasing at present prices allows businesses to lock in favorable rates while ensuring consistent supply throughout their operational cycle. Strategic inventory management becomes more feasible with these stable pricing structures.

Businesses can optimize their storage capacity and reduce waste by leveraging the extended shelf life of frozen products. This approach helps maintain steady cost controls while ensuring product availability during peak demand periods.

Modern freezing technologies have significantly improved product quality consistency in the frozen vegetables wholesale market. Each batch maintains uniform standards in terms of size, texture, and nutritional content, enabling businesses to deliver consistent quality in their final products.

Regular quality control measures and strict adherence to food safety standards ensure that all products meet or exceed industry requirements. This consistency in quality helps businesses maintain their reputation and customer satisfaction levels.

Maintain a consistent temperature of 0°F (-18°C) or below in commercial freezer units. Ensure proper air circulation and avoid temperature fluctuations to maintain product quality. Regular monitoring of storage conditions and proper rotation of stock are essential for optimal results.

When stored under proper conditions, frozen fries can maintain quality for up to 12 months, broccoli for 18 months, and processed garlic products for up to 24 months. However, it's recommended to follow specific manufacturer guidelines for best results.

Minimum order quantities vary by supplier but generally start at full pallet loads for each product type. Standard pallets typically contain 40-80 cases, depending on the product and packaging specifications. Volume discounts are often available for larger orders.

Hot News

Hot News2026-01-30

2026-01-27

2026-01-26

2026-01-23

2026-01-20

2026-01-16